F.A.Q.

- 1. Who is JYLUXE?

- JYLUXE is a premium packaging manufacturer located in Guangdong, China. Founded in 2005, the company currently operates over 6,000 square meters of printing production floors, equipped with 30+ advanced printing machines and 100+ experienced printing professionals. dedicated to delivering High-Value Packaging Solutions that reduce unnecessary production costs while enhancing packaging quality and value.

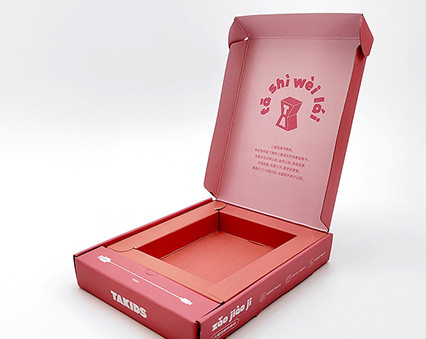

- 2. What Products Does JYLUXE Offer?

- JYLUXE's customized printing products are mainly divided into:

1. Packaging Printing: Folding boxes, gift boxes, rigid collapsible boxes, gable boxes, corrugated boxes, mailing boxes, lid and base boxes, drawer boxes, magnetic boxes, book-style boxes, lock bottom boxes, hanger boxes, display boxes, window boxes, shipping boxes, ribbon gift boxes, boxes with handles, custom-shaped boxes, bags, paper tubes, product labels, stickers, control panel labels, etc.

2. Commercial Printing: Brochures, product catalogs, hardcover books, children's books, notebooks, cards, envelopes, clothing hang tags, calendars, menu cards, folders, etc. - 3. Where is JYLUXE's factory? How can I visit?

- JYLUXE's headquarters factory is located in Bagua Ling Industrial Zone, Futian District, Shenzhen, China, approximately 45 kilometers from Bao'an Airport. You can learn about us through online videos or actual production photos, and we sincerely welcome you to visit and inspect our factory in person.

- 4. What services does Jyluxe offer?

- Jyluxe provides clients with integrated services including printing consultation, solution planning, printing material & process planning, printing quotation, sample production, print color management, post-press finishing production, quality control, transportation & delivery, etc.

- 5. Can you provide products or packaging featuring my logo or company information?

- Certainly. As we are a custom factory, your logo can be displayed on packaging boxes or marketing materials through printing, hot stamping, silver foil stamping, embossing/debossing, screen printing, etc. Additionally, based on your actual requirements, we can print your enterprise, brand, and product information on packaging boxes or marketing materials.

- 6. How to Get a Quote? What Information is Required?

- Please email us your customization requirements, such as: dimensions, materials, colors, surface treatments, design files, order quantity, desired effects or special requirements, etc. If you have previous printed samples, we welcome you to mail them to us.

Email: jyl-zq@jyluxeprint.com

mobile consultation: +86 185 6564 4413

Communicate with us via WeChat or other instant messaging tools. - 7. How do I get a packaging solution?

- You can communicate with our professional consultants through email and other contact information to get your solution.

1. If you are not clear about your packaging needs? We can provide integrated packaging solutions according to your industry, product protection and brand marketing needs, saving you packaging customisation costs, while enhancing packaging quality and value.

2. If you already have a design solution and are not sure how to do it better? Whether it is packaging printing or commercial printing needs, we can provide you with printing paper, materials, surface technology, finishing and other solutions based on your design, saving you unnecessary time and printing costs, while improving the quality of printing and application value. - 8. What is the customized packaging and printing process?

- As the packaging requirements of each enterprise differ, the packaging printing process can also vary, but it generally includes the following stages:

1. Requirement Consultation (quantity, material, structure, printing colors, finishing processes, etc.);

2. Solution Planning or Confirmation (① If you do not have a design plan: Jyluxe can provide integrated packaging solutions based on your industry, product protection, and brand marketing needs. ② If you already have a design plan: Jyluxe can plan solutions for printing papers, materials, surface finishes, finishing processes, etc., according to your design plan.);

3. Solution Confirmation (packaging structure, material, colors, processes, printing quantity, etc.);

4. Printing Quotation (quotation for printing solutions based on different materials, processes, qualities, and quantities);

5. Sample Proofing (digital proofing or press proofing, mailed or photographed for customer confirmation);

6. Printing Production (CTP plate making, color management, printing color control);

7. Post-Press Processes (surface finishing, precision processing, adhesive assembly, quality control);

8. Transportation and Delivery (packaging protection, transportation route optimization, logistics tracking);

9. After-Sales Service (follow-up, quality feedback, Optimize the details to achieve better results in future cooperation).

For more customized packaging and printing information and the actual cooperation process, please communicate and confirm with our professional consultants. - 9. How to obtain samples and what is the sample proofing time?

- 1. Stock samples (no printing required): Free mailing, you only need to pay the postage (or understand via photos and videos).

2. Digital proofing: 1-7 working days, relatively low cost (charged based on actuals; proofing fee refunded upon bulk order).

3. Press proofing: 5-15 working days, relatively high cost (charged based on actuals; proofing fee refunded upon bulk order). - 10. What is the production time for large-volume printing?

- Each project is unique, so it is difficult to provide an exact timeline. However, here is a general guide to assist you in planning:

1. Production Time: After you confirm the design files and samples (by mailing samples or photo confirmation),the large-volume production time for packaging printing is approximately 7-30 working days, and for commercial printing, it is approximately 5-20 working days. The specific time will be determined after communication with our customer service based on the actual order quantity and production requirements. (Note: Our order volume may increase significantly before the Chinese Spring Festival; or during Chinese statutory holidays, which may extend our proofing and production time.)

2. Pickup and Loading: 1-3 working days.

3. UPS, FedEx, DHL Express: 2-7 working days.

4. Air Freight: 5-10 working days.

5. Sea Freight (FCL - Full Container Load): 15-40 days; (LCL - Less than Container Load): 25-50 days.

The above are only estimated times. Factors beyond our control may cause delays. It is recommended that you allow some buffer time to avoid unnecessary surprises. - 11. What are your packaging and shipping methods?

- 1. Regarding Packaging: For both packaging printing and commercial printing, we adopt a method of first placing the products into moisture-proof bags, then packaging them in cartons. This ensures moisture resistance and prevents crushing. For products with larger quantities or volumes, we perform pallet reinforcement or utilize full container load (FCL) shipping methods to enhance product protection.

2. Regarding Transportation: We can employ various shipping methods such as air freight (DHL, FedEx, UPS, TNT),sea freight (CSCL, COSCO, APL, K'Line, Maersk, Hanjin),or other options including air, sea, road, and multimodal transport, based on the specific requirements of different regions and clients. Furthermore, we can optimize shipping routes and methods to help you save on shipping and customs costs, while ensuring transport efficiency. - 12. What are your payment terms and accepted currencies?

- We respect debit cards and credit cards issued by different countries. Mainly accepted payment currencies: US Dollar, Renminbi (CNY). Mainly accepted trade terms: EXW, FOB. Mainly accepted payment methods: Telegraphic Transfer (T/T),Letter of Credit (L/C),PayPal (for small sample fees),Alipay, etc.

- 13. Do you offer expedited orders?

- Depending on seasonal demand and packaging production scheduling, we may process expedited orders. It is recommended that you consult with our service advisor to understand whether we can currently handle expedited orders.

- 14. What is your minimum order quantity (MOQ)?

- To be precise, we do not have a minimum order quantity requirement, and we can customize orders regardless of the quantity you need. However, to help you obtain more favorable printing unit prices, we generally recommend for packaging printing: a custom order quantity of 1,000 - 2,000 pieces or more per design per batch; for commercial printing: a custom order quantity of 500 - 1,000 copies or more per design per batch.

- 15. What are the main market regions served by Jyluxe?

- Jyluxe provides integrated packaging solution services for companies worldwide that focus on brand building. The main service market shares are approximately: North America (30%),Europe (25%),domestic Chinese brands (15%),Oceania (10%),East Asia (10%),Southeast Asia (3%),Middle East (2%),Africa (2%),others (3%).

- 16. What are the main industries served by Jyluxe?

- Jyluxe adheres to a business philosophy of high value and quality, serving global excellent enterprises across various industries, especially those committed to building remarkable brands. The main industries served include: Cosmetics, Food, Coffee, Wine, Baking, Nutritional Supplements, Tea, Electronic Products, Hotels, Catering, Toys, Stationery, Watches, Jewelry, Luxury Goods, Toiletries, Perfumes, Pet Supplies, Pharmaceuticals, Education, Finance, Clothing, Electrical Appliances, Handicrafts, Artwork, Gifts, Retail, etc.

- 17. What are Jyluxe's production capabilities and equipment?

- After more than 20 years of development, Jyluxe Currently operating over 6,000 square meters of printing production floors, equipped with 30+ advanced printing machines and 100+ experienced printing professionals. This includes:

1. Printing Equipment: Features CTP inline platemaking systems and color management technology, with multiple Germany-made Heidelberg CX102 full-sheet 4-color/5-color/8-color printing presses (equipped with UV printing units),alongside a press fleet including 8-color label printing machines, control panel screen printing machines, HP Indigo digital presses, etc.

2. Post-Press Equipment: Heidelberg folding machines, fully automatic die-cutting machines, hot foil stamping machines, gluing machines, box mounting machines, laminating machines, binding machines, case-making machines, automatic shaping machines, V-grooving machines, saddle stitchers, perfect binders, and other finishing equipment for precision post-press processing.

3. Printing Team: A professional team with years of extensive experience in CTP platemaking, printing technology, precision post-press finishing, handcrafted assembly, packaging solution planning and design, quality management, order tracking, and consulting services, ensuring control over printing quality and value. - 18. What are the benefits of partnering with Jyluxe?

- 1. Customized Packaging Solutions: If you are unclear about your packaging requirements, we can provide ideal packaging solutions based on your industry, product protection needs, and brand marketing objectives.

2. Printing Paper and Process Planning: If you already have a design, whether for packaging or commercial printing, we can plan solutions for printing papers, materials, surface finishes, precision processing, etc., based on your design, thereby saving printing costs and enhancing print quality.

3. Professional Consultant Services: Jyluxe has established a team of printing consultants with extensive experience, providing you with 1-on-1 consultation, quotation, solution planning, quality follow-up, and other paper printing customization services.

4. Lower Prices, Higher Value: Jyluxe is committed to providing superior packaging solutions, saving you unnecessary costs while enhancing packaging quality and value, thereby boosting brand building and product sales. - 19. What is the process for custom commercial printing?

- Commercial printing includes items such as brochures, product catalogs, hardcover books, children's books, notebooks, cards, envelopes, clothing hang tags, labels, stickers, calendars, menu cards, folders, etc. The process may vary between different projects, but it generally includes the following stages:

1. Requirement Consultation (quantity, material, structure, printing colors, finishing, etc.);

2. Solution Planning (planning solutions for printing papers, materials, surface finishes, precision processing, etc., based on your existing design);

3. Printing Quotation (quotation for printing solutions based on different materials, processes, qualities, and quantities);

4. Sample Proofing (digital proofing or press proofing, mailing samples or photographing for customer confirmation);

5. Printing Production (CTP platemaking, color management, printing color control);

6. Post-Press Processes (surface finishing, precision processing, binding, assembly, quality control);

7. Transportation and Delivery (packaging protection, transportation route optimization, logistics tracking);

8. After-Sales Service (follow-up, quality feedback, optimizing details to achieve better results in further cooperation).

For more information on custom commercial printing and the actual cooperation process, please communicate and confirm with our professional consultants. - 20. What is the best format to provide for printing files?

- To ensure optimal printing results, it is recommended that clients provide printing files in vector formats such as AI, CDR, PDF, etc., while also paying attention to image clarity, font conversion to outlines, and leaving bleed margins with crop marks.

- 21. Will the printing color match the color on the screen?

- Not exactly! There is usually a certain difference between the printed color and the color on the screen.

This is mainly caused by the different color modes used for displays and printing. Displays use the RGB color mode, while printing uses the CMYK color mode for production. Additionally, different displays or printing on different paper materials will lead to color differences. To obtain accurate colors, it is recommended to use digital proofing or press proofing to confirm the printing color before large-volume production. Note that there may also be some difference between digital proofing and press proofing; moreover, for the same file, color variation of around 15% between different batches is considered normal. - 22. What is the difference between digital proofing and press proofing?

- 1. Digital Proofing: Digital proofing refers to the process of printing directly onto materials using a digital proofing machine, similar to desktop inkjet printing (but with larger and more advanced equipment, resulting in better output). Its main advantages include low minimum order quantity, low proofing cost, and fast turnaround, meeting the needs of most conventional packaging or commercial paper product proofing. The drawbacks are higher costs for mass production, relatively larger color differences compared to bulk printing, and relatively rougher die-cutting effects.

2. Press Proofing: This method closely resembles the bulk printing process and cost, requiring platemaking, printing machines, and post-press equipment for production. Its advantages include closer alignment with bulk printing in terms of color, craftsmanship, and quality. The disadvantages are higher proofing costs and longer lead times.

To balance cost efficiency and sample quality, Jyluxe typically recommends a combined approach of digital and press proofing, or selecting the most suitable proofing method based on specific project requirements. For details, please consult our professional advisors. - 23. How does Jyluxe ensure production quality?

- In addition to advanced printing equipment and a professional printing team, Jyluxe has established a printing consultant team with extensive experience. This team provides clients with integrated packaging solution services, including printing Needs Consulting, solution planning, printing material and process planning, printing quotation, sample proofing, production follow-up, post-press finishing, quality management, transportation and delivery, etc. This comprehensive approach better guarantees and manages production quality, allowing every client to collaborate with greater ease and confidence.

Contact a Professional Consultant

Get Packaging Solutions